Fig.2, Single, and Multiple Effect Evaporators configurations.

There are three criteria that affect the performance of an evaporator,

- Capacity (kg vaporized / time)

- Economy (kg vaporized / kg steam input)

- Steam Consumption (kg / hr)

Where Consumption = Capacity / Economy.

Economy (or steam economy) is the kilograms of water vaporized from all the effects (per kilogram of steam used). For single effect evaporator, the steam economy is ca. 0.8 (<1), which translates to 0.8 tons of steam needed to evaporate 1 ton of water.

So as to decrease the evaporator steam economy, the multiple-effect design uses the exhaust vapors from the product to heat the downstream evaporation effect and reduce the steam consumption.

The capacity of a multiple-effect evaporator (n effects) is ca. n*single effect evaporator capacity and the economy is about 0.8*n.

Evaporators need also pumps, interconnecting pipes, and valves that are required for transfer of liquid from one effect to another effect and they increase both the CAPEX and OPEX of the process.

|

Live Steam |

Vapor |

Steam Economy |

| 1-effect plant |

1 kg/h |

1 kg/h |

100% |

| 3-effect plant |

1 kg/h |

3 kg/h |

33% |

Table 1, Decrease of the evaporator steam economy by using a three effect evaporator

Single Effect (SE)

- Small capacity but wasteful energy (1 kg steam vaporize 1 kg water)

- Overall temperature drop for a single effect is somewhat equal to multiple effects

Multiple Effect (ME)

- Each individual effect will have a smaller temperature difference, thus high area of heating surfaces

- Capital cost more costly

- Operating cost- steam economy, only required for the first effect (1 kg steam vaporizes 3 kg water)

-

Evaporator Types

The temperature of the feed has an important effect on the evaporator’s economy and performance. If it is not already at its boiling point, then heat effects must take place. If the feed is above the boiling point, flash evaporation is used at the entry.

Normally, the feed solution is heated with a pre-heat exchanger to reduce the evaporation heat demand by transferring heat from the hot condensate to the feed stream.

The heated feed is then mixed with the evaporator liquid and the mixture is heated by the main heat exchanger which can use steam, electricity, hot oil or other forms of available energy. The mixture boils, producing a concentrated liquid stream and a water vapor stream which can be discharged or condensed.

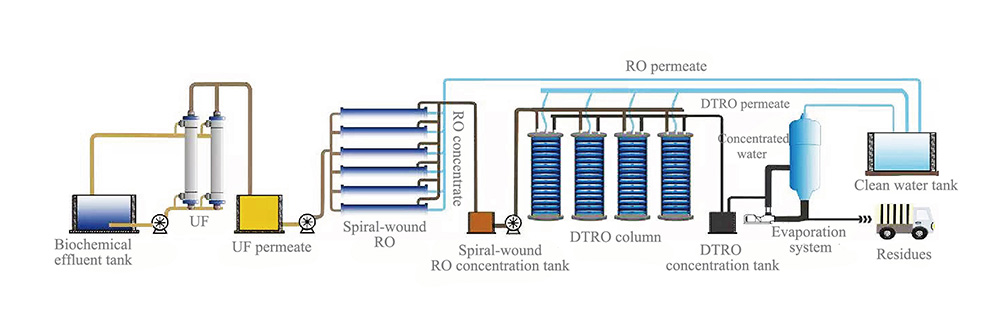

Vapor compression (VC) evaporation has been the norm ZLD technology for the last decades, recovering ca. 95 % water from the feed. The concentrated liquid stream (brine) can then be driven to a crystallizer in order to be solidified.

Evaporation is rather expensive and not economically feasible with large feed flow rates, which is why a pre-concentration step is applied to the ZLD process.

There are different kinds of evaporators,

-

falling film

-

rising film

-

forced circulation

-

scraped surface/thin film

-

combination evaporator

The main ones are,

- Falling Film Evaporators (FFEs)

FFEs have many energy-saving, multiple-effect evaporation, and mechanical vapor re-compression features. A FFE operates with a very small operating temperature and allows,

- easy controls

- fast start-up and shut down due to a minimal liquid hold-up

FFEs are chosen for viscous streams with small concentrations of suspended solids. An FFE has small to large flow rates capacity.

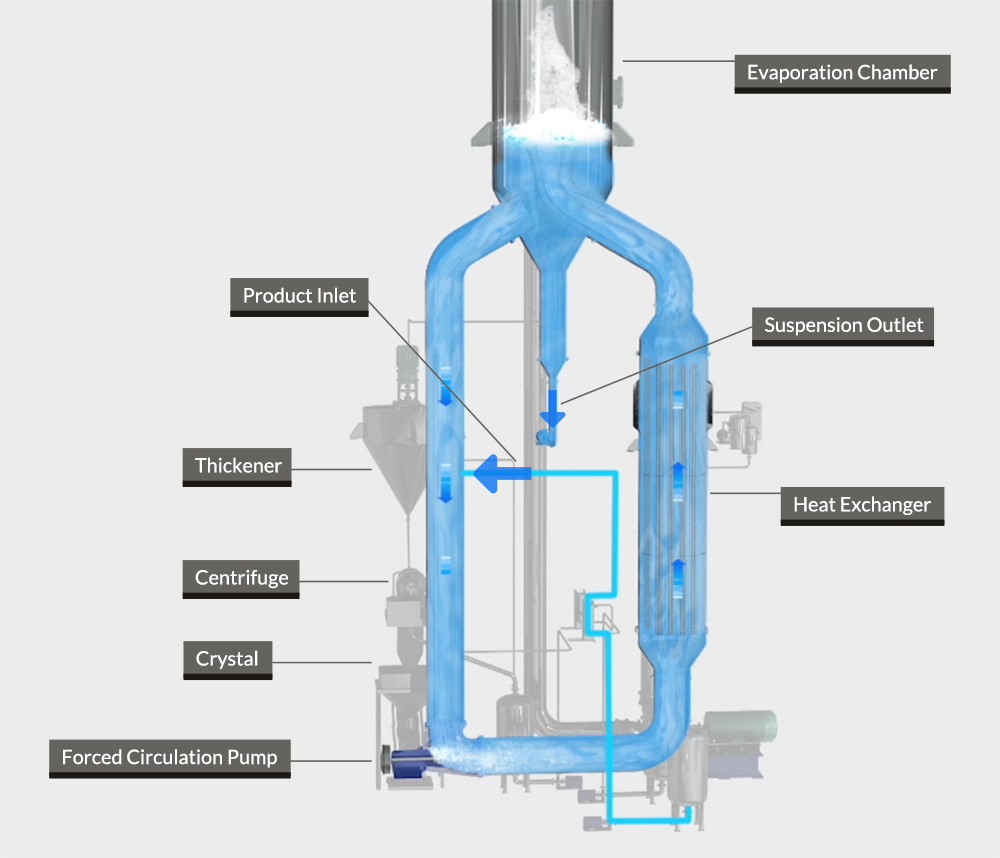

- Forced Circulation Evaporators (FCEs)

Because of the high circulation flow-rate and the evaporation taking place externally to the heat exchanger, FCEs are chosen for highly viscous streams containing a large concentration of suspended solids and fouling contaminants. It has medium to large flow rates capacity.

- Thin Film Evaporators (TFEs)/ Dryers

TFEs are mostly chosen in order to decrease the water content down to < 5% (crystallization). Like the FFEs, this technology is easy to control and fast to start up and shut down due to a very low liquid hold-up. TFEs are chosen for highly scaling products and highly viscous fluids. It has small to medium flow rates capacity.

Evaporators distillate stream is usually < 10 ppm TDS (Total Dissolved Solids). The most used is the FFE (also called brine concentrator) that can lead the feed concentration up to 300,000 ppm which leads to a boiling point rise (BPR) of the brine and requires either a large heat-transfer area (large CAPEX) or a large heat temperature (large OPEX).

- Process explanation

Evaporators can treat streams high chlorides concentration and theoretically separate the water from all of the dissolved species producing a stable solid product that can be landfilled and a high-quality distilled water product.

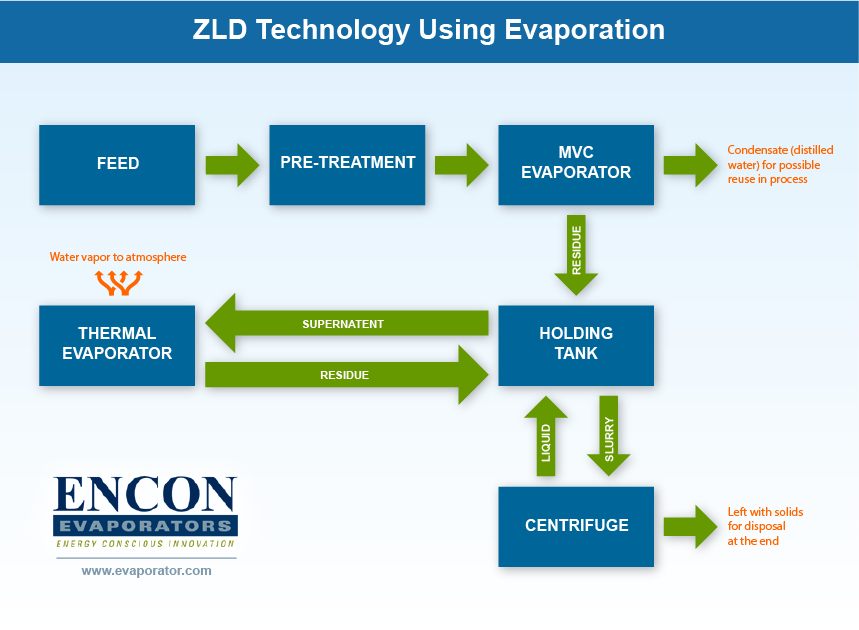

The steps in the evaporation process are (Fig.3),

- chemical addition (feed tank)

- preheating (feed preheater)

- deaeration

- primary evaporation (brine concentrator)

Fig.3, Evaporation process flow diagram and a photo of a real life module.

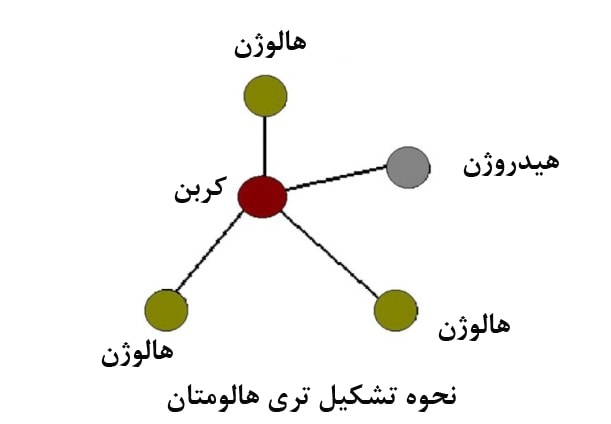

Steps 1&2; Acid is added to the feed tank to neutralize bicarbonate alkalinity in order for the solution to be preheated in the plate heat exchangers. Antiscalants are also added for preventing scaling in the preheaters with calcium carbonate.

Step 3; The pre-heated stream is degassed using steam from the evaporator (red line in Figure 3) to remove the dissolved carbon dioxide (alkalinity reduction), dissolved oxygen, and any other non-condensable gases in order to reduce the potential for corrosion of the evaporator.

Step 4; Most of the water evaporation takes place inside the brine concentrator vessel which is seeded with calcium sulfate to minimize scaling. The wastewater is typically saturated with calcium sulfate, which will precipitate and form scaling on the evaporator tubes. By using calcium sulfate seed crystals the dissolved calcium sulfate precipitates preferentially on the seed crystals rather than the evaporator tubes.

The process also requires electricity for the mechanical vapor compression (MVC) cycle. As MVC recycles the latent heat of vaporization, the energy input is quite low, in the range of 15 kWh/m3 of feed to minimize the size and cost of the vapor separator and compressor, evaporation occurs at atmospheric pressure.

- Energy saving

Some of the methods applied for minimizing the energy consumption of the evaporation plants include,

- Multiple effect arrangement (ME)

- Thermal vapor recompression (TVR)

- Mechanical vapor recompression (MVR)

- Mechanical vapor compression (MVC)

- Usage of waste energy

For evaporators, the MVC approach is the most widely used.

5.1 Mechanical Vapor Compression

In the MVC evaporator, heat is transferred to the circulating stream by condensing vapor from the compressor(s) (increasing the vapor’s temperature and pressure). In doing so it requires much less energy than a default evaporator.